Sawppy Issue: Getting E-Clip Slots Right Is Hard

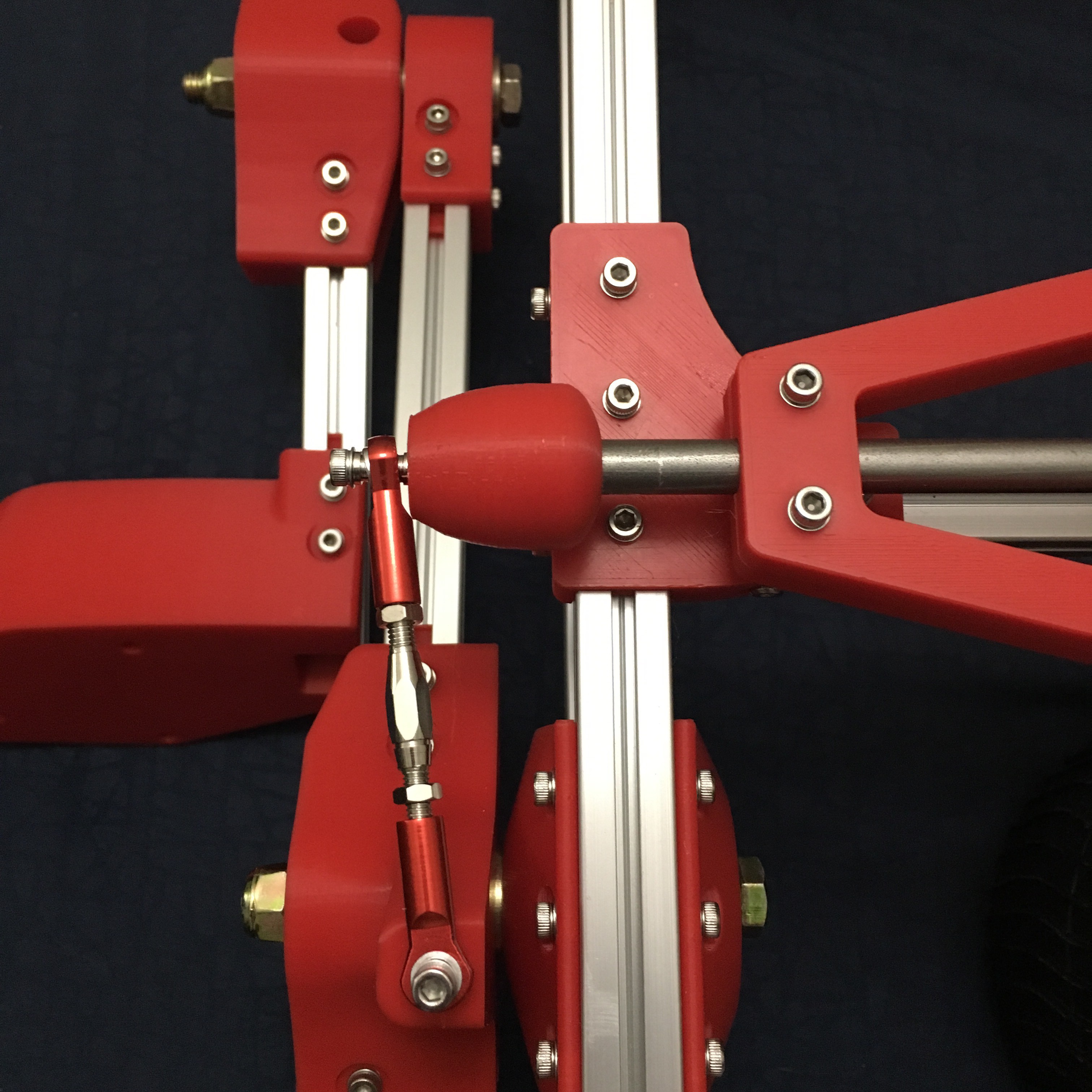

Closely related to the challenging heat-set inserts are the shafts their set screws bite into. I designed Sawppy to use 8mm metal shafts everywhere there is rotational motion: for wheel rolling, wheel steering, and rocker-bogie suspension articulation. Generally speaking there are three steps to fabricate Sawppy shafts:

- Cut to the proper length.

- Cut slots for E-rings.

- Cut flats for set screws. (For some of them.)

And it turns out the E-clips make everything trickier than it really needed to be. Unlike my ignorance with heat-set inserts, I knew E-clips are not very standardized, especially in their thickness. So my documentation couldn't really say what the proper lengths would be, I could only give the functional dimensions and tell people to add width of their E-clip slots.

For cutting those E-clip slots themselves, I documented a "Poor Man's Lathe" technique using two motorized tools, but this is not very precise. Fortunately, high precision is not required for a 3D-printed rover, the worst thing that happens is a rover whose suspension is a little bit wobblier than it would otherwise be.

Being a perfectionist, I was not happy with the hand-built results and arranged to cut a second set of Sawppy shafts with a manually operated metalworking lathe. And I knew imprecision would bother other Sawppy builders out there as well and not everyone could get access to a real lathe.

In the meantime, people have devised other workarounds. Ameer used M8 bolts and nuts instead. Using threaded fasteners instead of a solid shaft would put stress on the threads, but probably not terribly much for a little 3D printed rover. And it is definitely easier to work with.

The challenge with this approach is in tightening these bolts. If they are too loose, rover suspension will wobble and we've gained nothing. But if they are too tight, it puts too much axial load on the bearings and they seize up instead of turning freely as they should. I think there is a better way down the fastener path, and have a few ideas to test. If successful, a future Sawppy would use fasteners instead of fabricating shafts and also not unduly stress its threads or be finicky about amount of tightening torque.

I don't like it when some part of Sawppy is finicky, but I've come to accept that a tradeoff has to be made between finicky precision and a design that can be built by the widest range of rover enthusiasts. This became the most apparent when dealing with holes for these 8mm shafts.